- Mon-Fri 8 AM-4:30 PM EST

- Toll Free 1-877-343-4321

- customerservice@hotstampsupply.com

Hot Stamping Glossary

A-B

ABS

ABS is a type of plastic. It is a thermoplastic material often used for: musical instruments, golf club heads, automotive trim, protective headgear, luggage and protective carrying cases, small kitchen appliances, toys such as Legos, computer keyboards, power tool housing, wall socket face-guards, and 3D printing.

ABS is a type of plastic. It is a thermoplastic material often used for: musical instruments, golf club heads, automotive trim, protective headgear, luggage and protective carrying cases, small kitchen appliances, toys such as Legos, computer keyboards, power tool housing, wall socket face-guards, and 3D printing.

Adhesive Coat

![]() Hot stamp foil contains several important layers to make the great imprints desired. One of these is the adhesive coat. This allows the pigment/color layer to adhere, or stick, to the product. It is always the layer that comes in direct contact with the substrate. The adhesive coat varies based on what kind of material is being printed on.

Hot stamp foil contains several important layers to make the great imprints desired. One of these is the adhesive coat. This allows the pigment/color layer to adhere, or stick, to the product. It is always the layer that comes in direct contact with the substrate. The adhesive coat varies based on what kind of material is being printed on.

Alignment/Align

When you align things, you make sure they line up properly. In imprinting, the hot stamp die needs to line up or be aligned with the product so the graphic is imprinted properly.

C-D

Carrier Sheet

![]() A carrier sheet is one of the layers in a hot stamping foil that serves as a base or ‘carrier’ for the foil. It is placed facing the hot stamp die so when the die presses down, the pigment and other layers adhere to the product. Most carrier sheets are made from polyester and comes in varying thicknesses measured by Gage. The thinner the Gage, the crisper the release, which is best for fine detail.

A carrier sheet is one of the layers in a hot stamping foil that serves as a base or ‘carrier’ for the foil. It is placed facing the hot stamp die so when the die presses down, the pigment and other layers adhere to the product. Most carrier sheets are made from polyester and comes in varying thicknesses measured by Gage. The thinner the Gage, the crisper the release, which is best for fine detail.

Combination Stamping

The process by which 2 dies (called male and female) are used to emboss a product.

Die Temperature

A Hot Stamping Die temperature is usually controlled by a thermostat or temperature controller, which maintains head heat under normal cycle speeds in a range of 100 – 170 degrees Celcius.

E-F

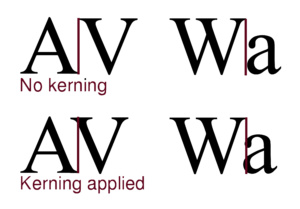

Fill-In

The bridging between letters that connect the characters. This may be intentional or accidental. In hot Stamping, printed text generally appear bolder than the hot Stamp Die so it is good to be careful not to place lettering too close together or it may cause accidental fill-in.

Footprint

The height, width, and length of the object being printed.

G-H

Gloss/Glossy

Glossy finishes make the application have a shiny, bright, or glazed appearance.

Halftone

A halftone of color is the use of dots varying in size or spacing that creates either a gradient-like appearance, or (in combination with another color’s halftone) creates a color blending effect. halftones are not used in traditional hot stamping, but we supply both full-color fusions and image transfers that may use halftones to create gradients and color variations.

Hit

A hit is a single impression from a hot stamping die. A two-color imprint would require two hits. When we do custom hot stamping, we charge a designated cost per hit.

I-K

Image Area

In hot stamping, the image area is the available area that you could apply your print to your part. It is based on printing limitations. For example, a product may only have an area of 1″x 5″ that a graphic can be hot stamped on, or the printing press may be limited to being able to print a 4″x5″ area.

L-M

Matte Finish

Matte finishes make the application have a flat, un-shiny appearance.

O-P

Opacity/Opaque

When something is opaque, the pigment completely covers other colors on which it is placed. In hot stamping, an opaque foil will not allow colors on the substrate to show through it. Opacity is the degree to which a material is opaque.

R-S

Register/Registration

A register is an accurate alignment of plates or colors one over the other in order to create multiple color images. In hot stamping, multiple dies with varying color can be used to layer colors together to make one whole image. Their registration is accurate when they are properly aligned to create the desired imprints.

T-V

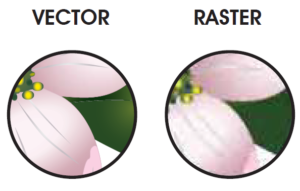

Vector/Vectorized Graphics

Vector graphics are created using mathematical points connected by lines/curves at an angle. Any collection of points that is connected on all sides creates a shape that can be filled in with a color or gradient. If an image is not vector, it is considered raster images. Vectors can be increased or decreased in size without loosing detail. When submitting a graphic for a hot stamp die, we request a vector graphic if at all possible. This is because customization and edits are easier to make to vector graphics. .ai .eps .pdf or .svg are the most ideal vector formats for our purposes.